Analysis of Manufacturing Process for Stainless Steel Valve Body Forgings

With the rapid development in various industries globally, stainless steel valves play an increasingly crucial role in fluid control across sectors such as petrochemicals, power generation, and food processing. The valve body, as a vital component of valve products, significantly influences the performance and quality of valves. This paper delves into the manufacturing process and techniques of ASTM A479M 304 material valve bodies, aiming to provide essential insights into the manufacturing technology of stainless steel valve bodies.

Detailed Analysis of Stainless Steel Valve Body Manufacturing Process

Test Materials

Experimental Materials

- Experimental Procedure and Analysis

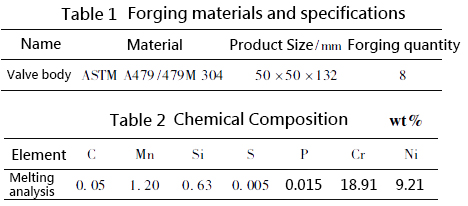

The experimental process involves smelting, refining, forging, heat treatment, inspection and testing, and machining. The raw materials for the experiment are carefully selected furnace materials to avoid introducing low-melting-point impurities into the steel during smelting. The steel ingots are smelted using an electric furnace combined with electric slag remelting to produce Φ500mm electric slag steel ingots. Table 1 provides details of the quantities of valve bodies manufactured using ASTM A479 /479M 304 for this experiment, while Table 2 presents the specific measured values of the chemical composition of the forgings.

- Experimental Process

Smelting and Refining Analysis: The selected raw materials undergo smelting to ensure purity, followed by refining to remove impurities. Electric furnace combined with electric slag remelting is used to smelt the steel ingots.

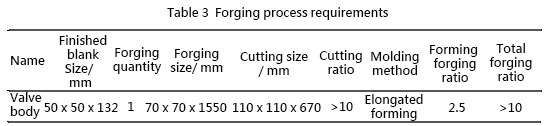

Forging Process: The steel ingots are forged into shape using a 1500T press and 3T forging hammer equipment. The ingots are heated to 1150°C, held at temperature, then forged into shape. Control over forging temperature and deformation is crucial to ensure uniformity and prevent crystal grain coarsening.

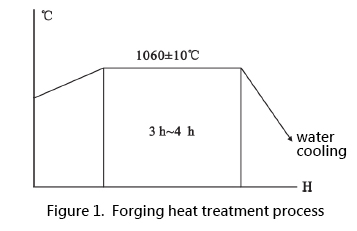

- Heat Treatment of Forgings: Heat treatment is performed in a resistance heating furnace with uniform heating capability and temperature control precision of ±10°C. The process involves attaching at least 2 thermocouples to each batch of workpieces and placing 2 additional thermocouples on the surfaces of the forgings to monitor temperature uniformity.

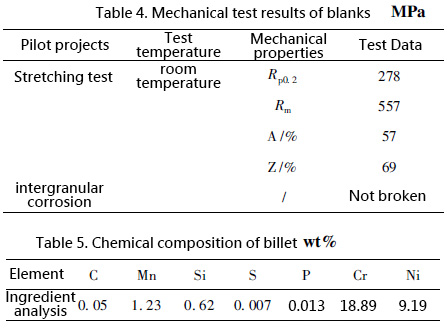

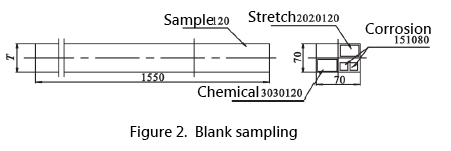

- Inspection and Testing: Samples are taken from the forgings according to specifications for chemical, intergranular corrosion, tensile, and impact testing. The remaining samples are marked for identification. Chemical and intergranular corrosion tests are conducted according to ASTM A262 standards.

Experimental Results

The experimental results (Tables 4 and 5) and the chemical composition of the forgings indicate that the manufacturing process for ASTM A479M 304 stainless steel valve body forgings effectively controls the use of electric slag, forging, heat treatment, and other techniques, achieving the expected goals for manufacturing and inspection. The inspection results of the forgings meet the specific technical requirements of relevant ASME standards.

Characteristics and Advantages of Material

Corrosion Resistance

ASTM A479M 304 material exhibits excellent corrosion resistance, making it suitable for long-term stable use in various harsh environments, making it suitable for a wide range of industrial applications.

High-Temperature Mechanical Performance

This material performs well under high-temperature conditions, boasting exceptional high-temperature mechanical properties to maintain stable operation in elevated temperature environments.High Cost-Effectiveness

Compared to other stainless steel materials, ASTM A479M 304 material offers a higher cost-effectiveness ratio, making it an ideal choice with stable performance and reasonable pricing.Through the analysis of the manufacturing process for stainless steel valve body forgings, it is concluded that effective control of techniques such as electric arc melting, forging, and heat treatment can ensure that the manufacturing process and inspection results of stainless steel valve bodies meet the expected targets. This manufacturing technology has the potential to be extended to the production of other forgings with similar materials, providing reliable technical support for the widespread application of stainless steel valve bodies across various industries.

Exploring Stainless Steel Valve Applications

Gate Valves

Stainless steel gate valves, fabricated using ASTM A479M 304 material, are renowned for their exceptional corrosion resistance and durability. These valves find widespread applications in sewage treatment plants, industrial pipelines, and water distribution systems.

Ball Valves

ASTM A479M 304 stainless steel is an ideal material for manufacturing ball valves, owing to its excellent high-temperature mechanical performance and corrosion resistance. These valves are extensively used in oil and gas industries, chemical processing plants, and petrochemical refineries.

Check Valves

Check valves crafted from ASTM A479M 304 material offer superior corrosion resistance and high-temperature stability, making them suitable for applications in water pump pits, blower rooms, and wastewater treatment facilities.

Characteristics and Advantages of ASTM A479M 304 Material

Enhanced Corrosion Resistance

ASTM A479M 304 stainless steel exhibits remarkable resistance to corrosion, making it an ideal choice for valves operating in corrosive environments such as chemical plants and marine applications.

Superior Mechanical Properties

The high-temperature mechanical performance of ASTM A479M 304 material ensures the longevity and reliability of valves even under extreme temperature conditions, making them suitable for applications in power plants and industrial furnaces.

Versatile Applications

Due to its versatility and high cost-effectiveness, ASTM A479M 304 material is widely used in various valve types, including gate valves, ball valves, and check valves, catering to the diverse needs of industries such as pharmaceuticals, food processing, and wastewater treatment.

Conclusion

The analysis of the manufacturing process of stainless steel valve bodies is an in-depth exploration of the manufacturing process of this critical component, helping us better understand the manufacturing principles and processes of valve bodies. With continuous technological advancements and expanded application scopes, stainless steel valve bodies are expected to play an even more significant role in the future, providing more reliable and efficient fluid control solutions for various industries.