Ball Production Line: Engineering Spheres of Excellence

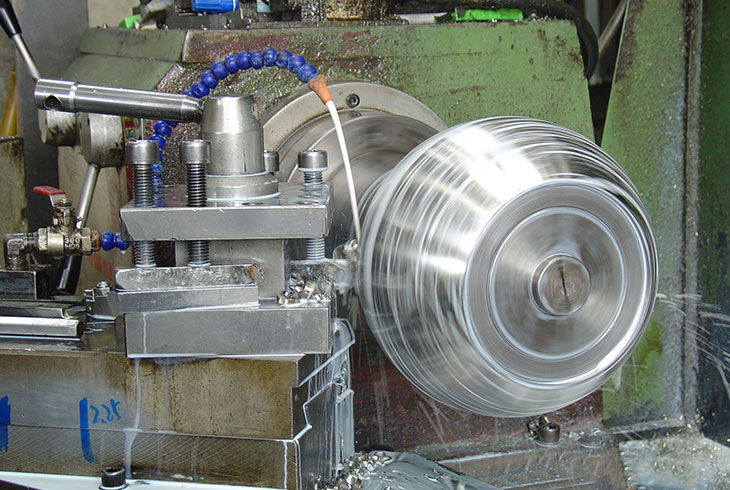

Our OEM Services extend to the Ball Production Line, where engineering excellence creates spheres of unparalleled performance. Ball is the most important part of a ball valve, and the machining quality affects directly the performance of the valve’s operation. Each ball is made from raw castings, internal diameter & outside diameter machining, slotting, pickling, de-burr, ultra-sonic cleaning, mirror polishing, marking to packing. Each step needs strict control and protection. Be it for valves, industrial processes, or cutting-edge applications, our ball production exemplifies the harmony between innovation and precision. The 3D measuring machine provides accurate dimension checks and reports.

- Products: Investment Casting, Sand Casting, Bar Stock, Centrifugal Casting & Forged Casting Balls

- Certificate: ISO 9001:2015

- Materials: Stainless Steel & Carbon Steel

- Sizes: from 1/4" to 36"

Testings:

Spectrometer, Micro 3D measuring machine, Round pak, Surface Roughness testing.