Choosing the Right Ball Valve: Understanding the Differences between 1pc, 2pc, and 3pc Varieties

Threaded Ball Valve Socket Weld Ball Valve Butt Weld Ball Valve Flanged Ball Valve Contact INOX-TEK

Choosing the right ball valve is essential for any plumbing or industrial project. With various options available in the market, understanding the differences between 1pc, 2pc, and 3pc varieties can help you make an informed decision.

The 1pc ball valve is a solid, one-piece design that offers simplicity and reliability. It is commonly used in residential applications and low-pressure systems. On the other hand, the 2pc ball valve consists of two separate pieces that can be easily dismantled for maintenance or repairs. This type of valve is popular in industrial settings, where frequent servicing may be required.

For more complex systems, the 3pc ball valve is the go-to choice. This variety allows for easy installation and maintenance, as the body can be disassembled without cutting the pipe. It is widely used in industries such as oil and gas, chemical processing, and water treatment.

Understanding the differences between these ball valve varieties will enable you to select the most suitable option for your specific requirements. Whether it's a residential project or an industrial venture, choosing the right ball valve ensures optimal performance and longevity.

Understanding the different types of ball valves - 1PC, 2PC, and 3PC

Ball valves are widely used in various industries for their ability to control the flow of fluids. Understanding the differences between the three main types of ball valves - 1pc, 2pc, and 3pc - is crucial in making the right choice.

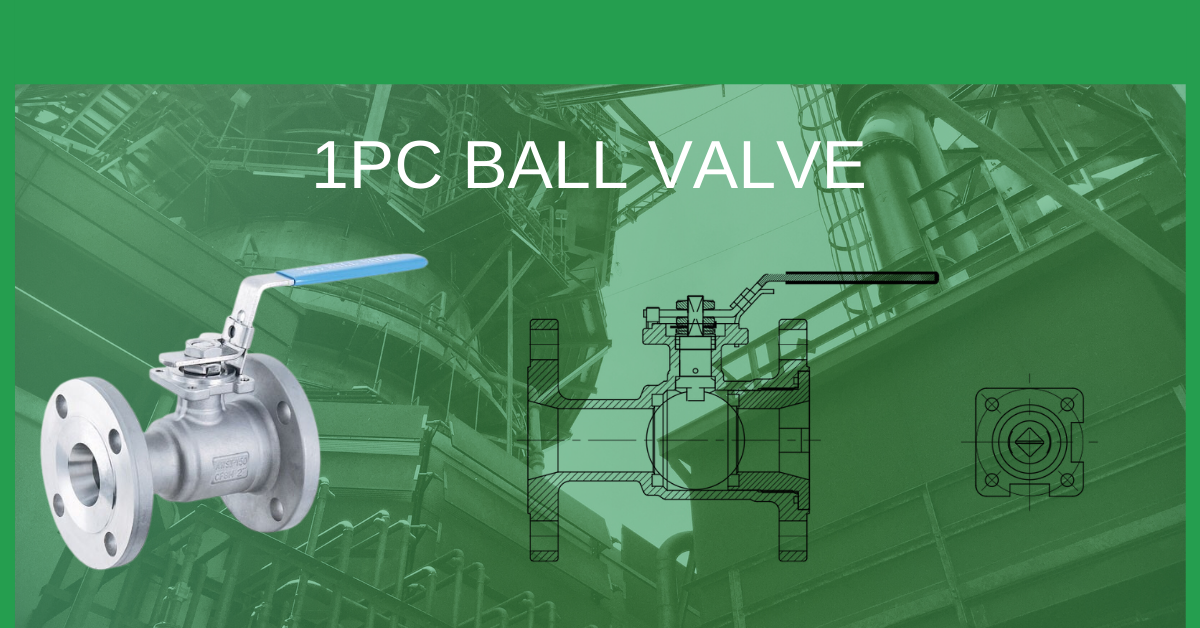

1PC Ball Valves

The 1pc ball valve is a compact and straightforward design consisting of a single body. It is made from a solid piece of metal, typically stainless steel, which provides durability and resistance to corrosion. This type of valve is commonly used in residential applications, such as household plumbing systems.

Advantages of 1pc ball valves include their simplicity and reliability. With fewer parts and connections, there is less chance of leakage or failure.

Additionally, the one-piece construction eliminates the need for extra seals, reducing the risk of potential leaks.

On the downside, 1pc ball valves have limited options when it comes to size and pressure ratings. They are typically suitable for low-pressure systems and have a smaller range of sizes available compared to other types of ball valves. However, for applications where simplicity is key, such as residential plumbing, 1pc ball valves are a practical choice.

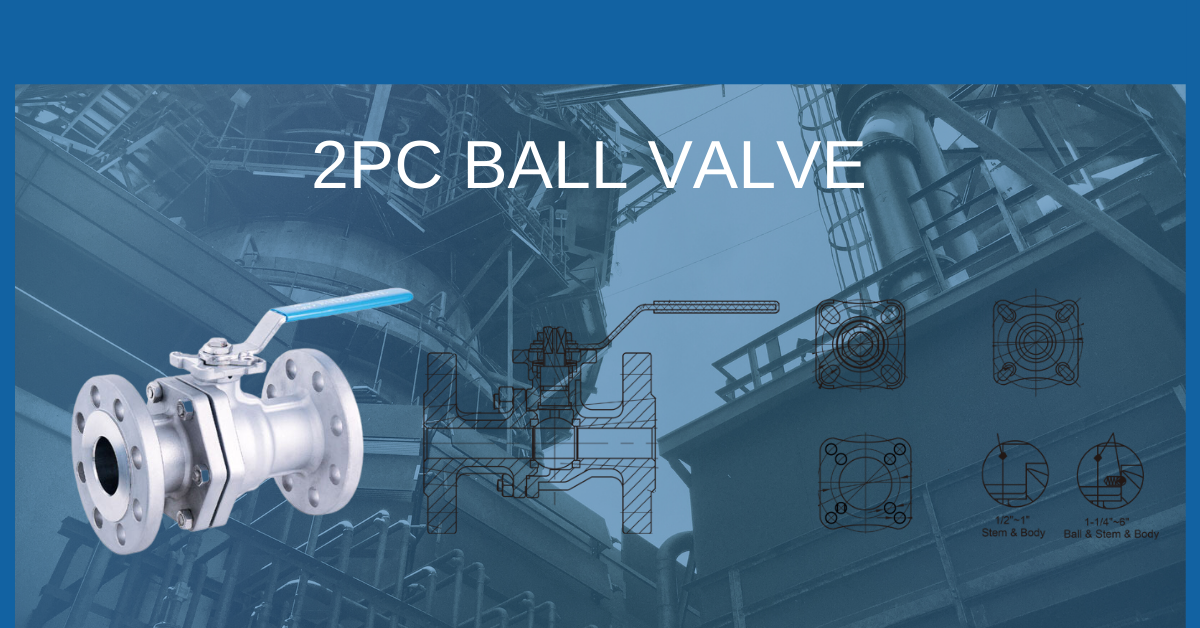

2PC Ball Valves

The 2pc ball valve consists of two separate pieces that can be easily taken apart for maintenance or repairs. This design offers flexibility and ease of servicing, making it popular in industrial settings where frequent maintenance is required.

One of the main advantages of 2pc ball valves is their ability to be disassembled without cutting the pipeline. This feature saves time and effort during maintenance, as the valve can be easily removed and reinstalled.

Additionally, 2pc ball valves offer a wider range of sizes and pressure ratings compared to 1pc ball valves, making them suitable for a variety of applications.

However, the presence of multiple parts and connections in 2pc ball valves increases the risk of potential leaks. Regular inspections and proper maintenance are necessary to ensure optimal performance and prevent any issues. Despite this drawback, the convenience of easy maintenance makes 2pc ball valves a popular choice in industries where downtime must be minimized.

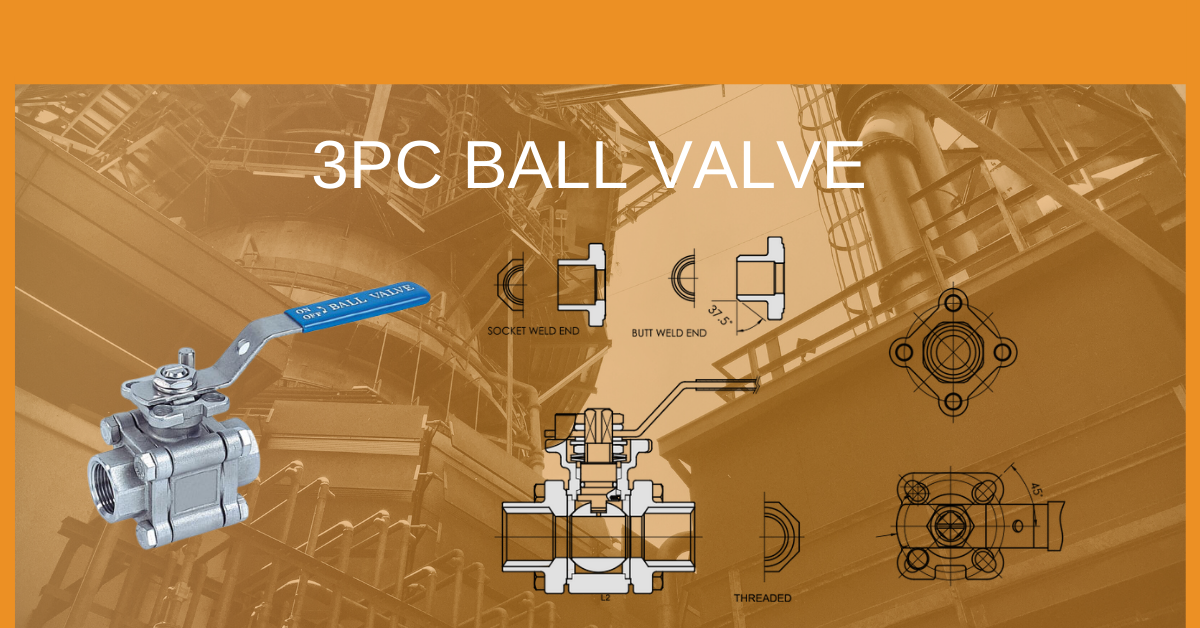

3PC Ball Valves

For more complex systems, the 3pc ball valve is the preferred choice. This type of valve consists of three separate pieces that can be easily assembled and disassembled without cutting the pipe. The body of the valve can be taken apart, allowing for easy installation and maintenance.

The advantages of 3pc ball valves are their versatility and ease of maintenance. The ability to dismantle the valve without disrupting the pipeline makes it an ideal choice for industries such as oil and gas, chemical processing, and water treatment. The three-piece design also provides flexibility in terms of customization and repair, as individual components can be replaced as needed.

However, 3pc ball valves are generally more expensive compared to 1pc and 2pc varieties. The additional components and assembly complexity contribute to the higher cost. Despite the cost factor, the benefits of easy installation and maintenance make 3pc ball valves the go-to choice for industries that require frequent servicing and system modifications.

Advantages and Disadvantages of 1PC Ball Valves

A one-piece ball valve belongs to the category of manual valves. The ball valve uses a spherical ball with a circular channel as the closing element, and the ball rotates around the axis perpendicular to the channel to achieve the opening and closing actions of the valve. The closing element of the ball valve is a perforated sphere that rotates around the axis perpendicular to the channel, thereby achieving the purpose of opening and closing the channel. Ball valves are mainly used to cut off or connect pipeline and equipment media. They can also be used for fluid regulation and control. Ball valves have low fluid resistance, a simple structure, small size, light weight, tight reliability, convenient operation and maintenance, and do not cause erosion of the valve sealing surface. They are suitable for a wide range of applications.

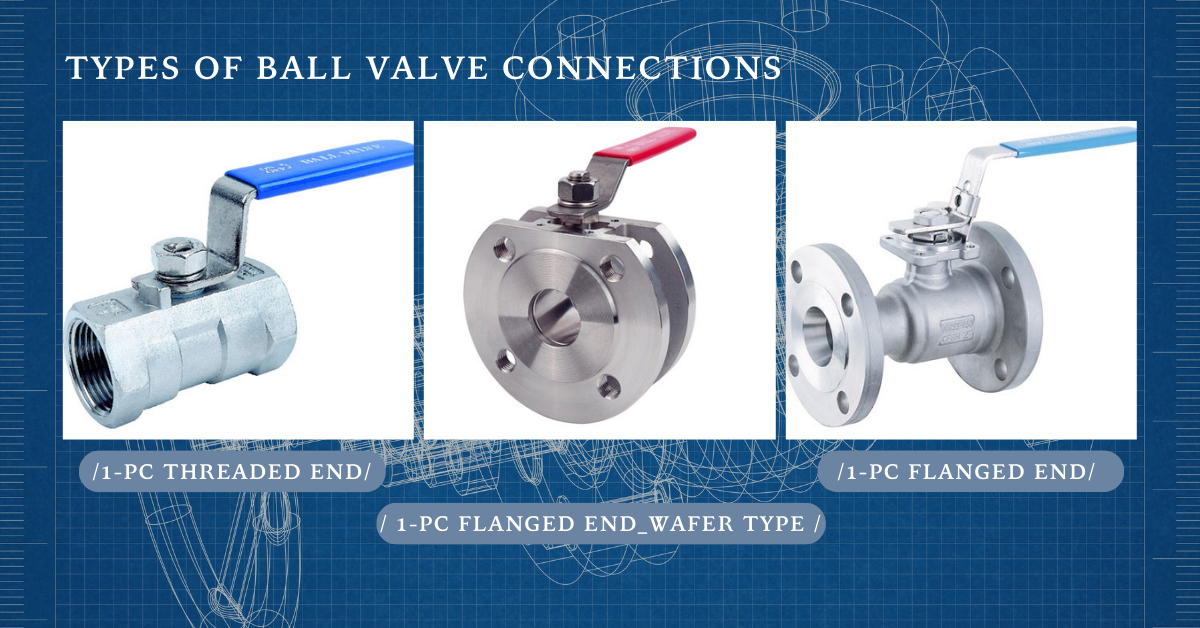

A one-piece ball valve has threaded connections, flange connections, and clamp connections. A one-piece internal threaded ball valve cannot be made into a high platform and cannot be equipped with electric, pneumatic, and other actuators.

Advantages:

- Simplicity and reliability in design.

- Fewer parts and connections reduce the risk of leakage.

- Suitable for low-pressure systems.

Disadvantages:

- Limited options in terms of size and pressure ratings.

- Not ideal for high-pressure industrial applications.

Advantages and Disadvantages of 2PC Ball Valves

The body of a two-piece ball valve is composed of a main body and a secondary body. After the ball core, valve seat, and valve stem are installed in the main body, the secondary body is connected to the main body through threads or bolts. Its ball core passage is of full diameter, with low flow resistance and large flow capacity. It is mainly used in normal pressure and high-pressure environments, and valves with a nominal diameter below DN50 also belong to the two-piece type.

Advantages:

- Easy to dismantle for maintenance or repairs.

- Wider range of sizes and pressure ratings.

- Suitable for various industrial applications.

Disadvantages:

- Increased risk of potential leaks due to multiple parts.

- Requires regular inspections and proper maintenance.

Advantages and Disadvantages of 3PC Ball Valves

The three-piece ball valve is similar to the two-piece ball valve, consisting of a main body and two secondary bodies, hence the name "three-piece" ball valve. After the ball core and valve stem are installed in the main body, the secondary body is installed in the valve seat, and the main and secondary bodies are connected as one through bolts. Its ball core passage is also of full diameter.

The main feature of the three-piece ball valve is that it can be maintained online, which is very convenient. Loosen the screws on the valve body, remove a bolt passing through the main body, rotate the main body to replace the valve seat sealing ring. You can also completely remove the main body bolts and disassemble the main body for maintenance. The secondary body remains in the pipeline, avoiding the need to disassemble the entire ball valve, greatly reducing the workload of maintenance.

Advantages:

- Versatility and ease of maintenance.

- Ideal for complex systems and industries with frequent servicing.

- Flexibility in customization and repair.

Disadvantages:

- Generally more expensive than 1pc and 2pc varieties.

- Higher cost due to additional components and assembly complexity.

Factors to Consider When Choosing A Ball Valve - Size, Material, Pressure Rating, and Application

- Size: Ensure the valve size matches the requirements of your system.

- Material: Select materials based on factors like corrosion resistance and durability.

- Pressure Rating: Choose a valve that can handle the pressure levels of your application.

- Application: Consider the specific needs of your project or industry.

Common Applications for 1PC, 2PC, and 3PC Ball Valves

- 1PC Ball Valves: Residential plumbing systems, low-pressure applications.

- 2PC Ball Valves:Industrial settings, applications requiring frequent maintenance.

- 3PC Ball Valves:Oil and gas industries, chemical processing, water treatment.

Maintenance and Troubleshooting Tips for Ball Valves

- Regular inspections for signs of wear or leaks.

- Lubricate moving parts as per manufacturer recommendations.

- Address leaks promptly to prevent system damage.

Choosing the Right Ball Valve for Your Specific Needs

Consider the nature of your project, the frequency of maintenance, and the system's pressure requirements when making a decision. Each type has its advantages, and selecting the right one ensures optimal performance and longevity.

Conclusion

In the dynamic landscape of ball valves, the selection process involves a careful consideration of design nuances and application-specific requirements. Each variant—1pc, 2pc, and 3pc—brings its unique advantages to the table.

1pc Ball Valves, with their streamlined design and reliability, serve admirably in residential plumbing but may find limitations in more demanding industrial scenarios. Here, simplicity is the key, and cost-effective solutions often align with the requirements.

2pc Ball Valves emerge as versatile contenders, providing a balance between ease of maintenance and suitability for various industrial applications. They become particularly relevant in settings where downtime must be minimized, making them a popular choice.

For the more intricate systems and industries demanding frequent servicing, the 3pc Ball Valves from INOX-TEK take center stage. The ability to assemble and disassemble without cutting the pipe underscores their versatility. Industries such as oil and gas, chemical processing, and water treatment benefit from the flexibility offered by the 3pc design. Despite a relatively higher cost, the advantages of easy installation and maintenance position them as the preferred choice for dynamic environments.

As industries evolve, it becomes evident that the choice of a ball valve is not a one-size-fits-all decision. It hinges on project-specific needs, maintenance considerations, and the critical factor of cost-effectiveness. INOX-TEK stands at the forefront of this narrative, providing not just ball valves but solutions tailored to the evolving demands of modern industries. Their range of offerings includes robust 1pc options for residential applications, versatile 2pc valves for industrial demands, and sophisticated 3pc valves for complex systems.

Choosing the right ball valve is not just about acquiring a component; it's about securing a solution that aligns seamlessly with your project's requirements. With INOX-TEK, this choice becomes a strategic investment, ensuring optimal performance, longevity, and adaptability to the ever-changing dynamics of industrial processes.